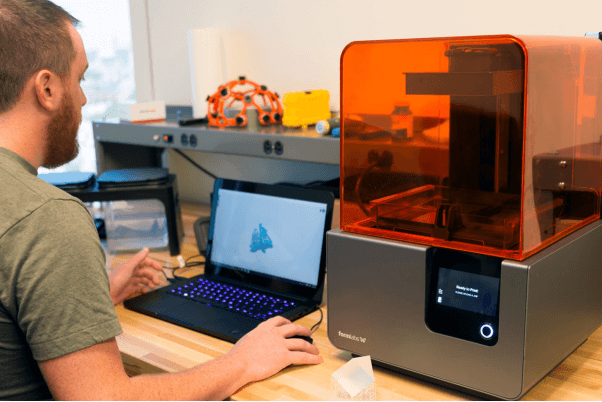

A 3D printer is a machine that facilitates the 3D printing technology by using computer-aided design (CAD) to create a three-dimensional object through a layering method. It is one of the most captivating developments in printing history; hence many companies have embraced 3D printing. The printers produce custom items using high volume and quality resin and are becoming more affordable for all users, e.g., the resin 3d printer under $300. 3D printing technology is used in almost all industries for different applications like dental products, consumer products, and reconstructing evidence in forensic pathology. In this extract, we look at the Importance of 3D printing technology.

Importance of 3D Printing Technology

The demand for 3D printing is growing due to some of the revolutionary benefits that it can provide. They include;

- Design Flexibility

The traditional printing processes restricted users when it came to designing options. Each change in design requires a new tool, die, or mold. With 3D, it allows for the designing and printing of more complex products. Any printer can create anything that fits its build volume. It enables the inclusion of various materials, a wide range of colors and textures.

- Rapid Prototyping and Increased Productivity

The technology allows for designing, manufacturing, and testing customized products in a short time. A CAD model can be transformed into a reality in a few hours. Traditional methods can take weeks or months to go from the design stage through to the production stage.

- Cost Reduction

It is a single step manufacturing process hence saves on costs associated with the use of different machines. The cost of materials is also reduced as only the needed materials are used, with little to no waste production ( additive manufacturing ). The printer can also be pre-set to work on its own; therefore, no manual workers are required; thus, no labor costs are incurred.

- Easily Accessible

Compared to traditional setups,3D printing systems are much more accessible and can be used by a more extensive range of people. It is almost entirely automated, requiring fewer personnel to run, supevise, and maintain it, unlike other manufacturing systems that have many complicated machines.

- Quality and Consistency

3D printing technology allows step by step assembly of products. Good designs are used, leading to good quality prototypes. There is improved consistency as errors are immediately noticed; thus, the overall number of wasted materials and defective or inconsistent parts is lowered.

- Production on Demand

Printing is done only when required using CAD or STL files; thus, there is no need to print in bulk, and you don’t need a lot of space to stock up inventory. 3D designs are saved in a virtual library and can be retrieved and printed when required.

- Product Testing

It is possible to physically touch and feel a 3D printed object to check whether it has flaws in its design. If you detect an error, you can change the CAD file and then write a new version.

Conclusion

Knowing the pros of the 3D printing technology, you can now understand why it is becoming revolutionized across the world.3D printers are a good investment when selecting a product development method.