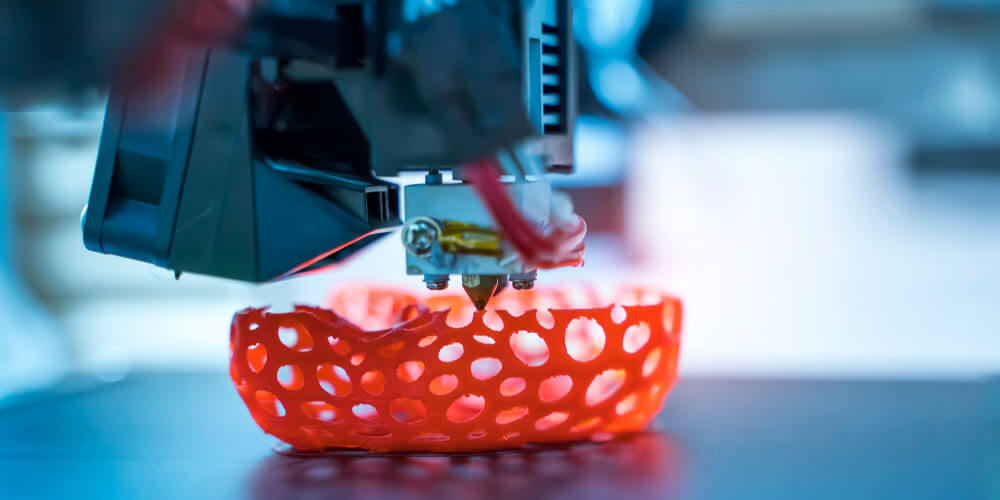

Rapid prototyping is an umbrella of processes used to produce prototypes direct from the design or mold. The 3D prototyping service offers a quick and cost-effective solution for your projects and product development thanks to the short lead time and realistic parts for reliable tests. In this write-up, we discuss the factors to consider when choosing a rapid prototyping process

Factors to Consider When Choosing a Rapid Prototyping Process

The rapid prototyping process you select will determine the success or failure of your product creation. It is good to have an idea of how you want your final product to look. Prototypes differ from each other as the project, products, and design components are not the same. These factors should be considered at the beginning of the selection process.

1. Purpose

The purpose of a new product varies depending on which stage of the New Product Development (NPD) you are in. Usually, there are four stages that have functionality requirements for risk elimination. They include product planning and task clarification, conceptual design, embodiment design, and detailed design stage.

You need to have proof of concept models, units for demonstration, and industrial design models in the planning stage. Prototyping techniques are used to create 3D printed parts and mock-ups made of cardboard.

In the second stage, scaled designed assemblies and user interfaces are needed. The embodiment design stage is where the exploration of prototypes takes place, and the details are essential. The final step is an indication that any prototype made in that phase shall be used for testing.

2. Quantity

Before approaching a designer, it is vital to know the number of end products you want to be made. Some technologies cost less when used on small quantities of products, while others require more money to produce a large number of items.

More volume also determines the amount of time taken. Large parts need more printing time; hence, most manufacturers may charge based on their time and amount of work. It is familiar with the additive manufacturing process.

3. Quality of Products

The accuracy of your product dictates the prototype process to be used. High-fidelity prototypes are of a higher quality than low-fidelity prototypes. The prototype’s quality compared to your final product must be considered. Suppose you want an item completely similar to the model.

In that case, the processing technology and post-processing differ from when the prototype and end product have a distinct difference. To some extent, your budget also determines the quality and accuracy levels. Those with better quality will cost more than low-quality products.

4. Complexity

How complex a part is dictates your choice of the rapid prototype process. Design with small complicated parts is better produced by additive manufacturing. Machine parts can be manufactured through the subtractive manufacturing process, while those produced through injection molding are made using 3D printing.

Bottom Line

Choosing the proper process to create your prototype is crucial. The above factors give you a clear understanding of what to look for starting the selection steps. The quality of the product and testing is based on how well the prototype simulates your product. Choose the type you want to apply or seek guidance from an expert in rapid prototyping.